There are many variations of passages available sure there majority have suffered alteration in some form by inject humour or randomised words which don't look even slightly believable.

Reventiss Biotech Private Limited

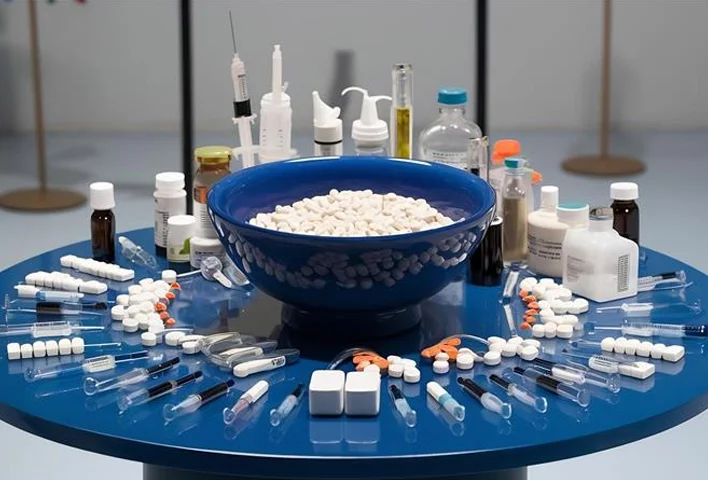

Reventiss Biotech is an Indian pharmaceutical manufacturing firm, which was founded in 2019. It is a company based in Mathura, Uttar Pradesh and is specializing in the formulations of pharmaceuticals and nutraceuticals based on quality. Reventiss Biotech is a third party manufacturing partner and assists the brands with regulated production, documented procedures, and certified quality systems. The company has a good experience in neuro and psychiatric product segments and exports pharmaceutical products to foreign markets with acceptable logistics and regulatory practices.

From Raw Material to Release

Raw Material Control

Every batch begins with sourcing of approved raw materials. Before the production, materials are inspected, identified and documented, to maintain consistency, traceability and adherence to specified pharmaceutical quality standards.

In-Process Quality Monitoring

Quality tests are carried out at each production level. The parameters like weight, uniformity, and composition are kept in check to ensure that the accuracy of the batch and minimize the deviations during the manufacturing process.

Finished Product Testing

Finished products are tested physically, chemically and microbiologically. Batches that are of approved specifications only proceed to the next stage of packing and release making sure that the products are safe and therapeutically reliable.

Batch Release and Documentation

Before release, batch records are examined by the authorized personnel. Full documentation is done to ensure that the requirements of WHO-GMP norms, regulations, and uniform quality are met in the domestic supply and export consignments.

What You Gain With Us

Focused research teams develop stable, compliant and the market ready nutraceutical formulations.

Over 800 approved products support the faster launches and the regulatory confidence.

Each formulation follows the current food regulatory frameworks from development stage.

Raw materials, processing and the final packing follow the controlled quality checkpoints.

Single-point assistance for the formulation, approvals, documentation and manufacturing queries.

Wide product range including the in-licensed and innovation driven nutraceutical offerings.

Premium In-Licensed Nutraceutical Ingredients

Wide access to the approved vitamins, minerals and botanical extracts supports the consistent efficacy and the formulation reliability.

NESM Joint Health Ingredient

Clinically proven nutritional ingredient that is utilized in the maintenance of the joint strength and connective tissue.

Imunoglukan Bioactive Polysaccharide

Scientifically studied polysaccharide that is used in the upper respiratory support of children and adults, which is produced in Slovakia.

KMF Probiotic Ingredient

Kluyveromyces marxianus B0399, a special probiotic strain, which can be used by humans, is a strain found in Italy.

Krill Oil Omega Ingredient

Very bioavailable omega source provided by one of the world leaders in the production of krill oil.

Smart Infrastructure.Strong Output.

Modern Manufacturing Equipment

Modern machines used in production are geared towards pharmaceutical production, which help in the accuracy, efficiency, and uniformity of production of all approved dosage forms.

Regular Technology Upgrades

Machines and instruments are periodically upgraded to ensure that they are performing, precise, and in line with the current manufacturing of pharmaceutical needs.

Certified Facility Layout

The unit adheres to approved layouts that facilitate unhindered flow of materials, contamination, and adherence to the regulated standards of pharmaceutical production.

Documented Operational Workflows

There are documented procedures that all operations are governed by, and this means that there is control in the processes and that quality and regulatory requirements are met.

Leadership with Purpose

Virendra Yadav leads Reventiss Biotech Private Limited who has a high emphasis on ethical production and compliance with the regulations. His leadership focus is on the quality uniformity, openness of business activities, and the rigorous discipline of process management. He also advocates long-term relationships, systematic growth strategy and reliability of manufacturing results in accordance with the demands of the industry.

Our Third Party Manufacturing Process

Client submits approved brand name and final product composition.

Design of packaging and labeling specifications according to the regulatory requirements.

Start of manufacturing upon all approvals and documentation.

Checking of quality, batches and dispatching of completed products.

New projects are completed within thirty to forty days through coordinated supply.

Essential Documents Checklist

In order to start third party manufacturing services, clients will be required to provide necessary regulatory and identification documents to comply and verify the agreement.

- Pharmaceutical operations: valid Drug License.

- Certificate of registration of GST.

- PAN card of the associate

- Identity verification from Aadhaar card.

- Bank cheque details (cancelled)

Original documents are demanded when agreement finalization and verification are to take place. Packaging Aligned with Compliance

Label Design and Regulatory Details

There are labels such as product name, composition, statutory and batch information to ensure compliance and clarity.

Color Selection and Visual Consistency

Colors are based on brand regulations, which guarantee the visual consistency and good recognition in the market.

Product Description and Information Accuracy

Descriptions are precise, comprehensible and consistent with accepted medical and use data.

Certified Packaging Materials and Safety

Certified materials assure the safety and stability as well as compliance of the products in storage and transportation.